Solutions

PROJECT AND CONSULTANCY

We conceptualize 100% environmentally friendly and 100% efficient systems that recover all kinds of metals separately through our electronic waste recycling solutions that suit your capacity needs.

We provide manufacturing and system consultancy services.

Our Working Principles

We listen to you. We solve your problems by utilizing the experience we accumulated since 1975.

We conceptualize the system and ensure that your production processes become more efficient by collaborating with you during manufacturing and purchasing processes.

After conceptualization of the system as a whole, we define the priorities and stage the process for attaining the maximum profit as per your investment financing resources.

ODORLESS & FLUELESS RECYCLING AND REFINING SYSTEM

We attain 100% recycling and 98-99% refining efficiency with our machinery that ensures 100% environmental-regulation-compliant flue gas and effluent disposal.

Discharging systems compliant with EU Norms are being applied for treated chemical flue gas and effluent discharge.

We conceptualize a machinery park ranging from 5 to 100 kilograms of capacity, and install the machinery accordingly.

We provide know-how training related to chemical processes required for producing gold of 999.9 purity; and silver, palladium and platinum of high purity.

We deliver the systems including installation and training services.

100-kg-capacity Recycling and Refining Machine

2X25-kg-capacity Recycling and Refining Machine

25-kg-capacity Recycling and Refining Machine

Though it has a capacity of 25 kilograms, this is a complete piece of machinery designed for recycling 1 to 25 kilograms of material or refining scrap precious metal of the same amount.

7-kg-capacity Recycling and Refining Machine

Though it has a capacity of 7 kilograms, this is a complete piece of machinery designed for recycling 1 to 7 kilograms of material or refining scrap precious metal of the same amount.

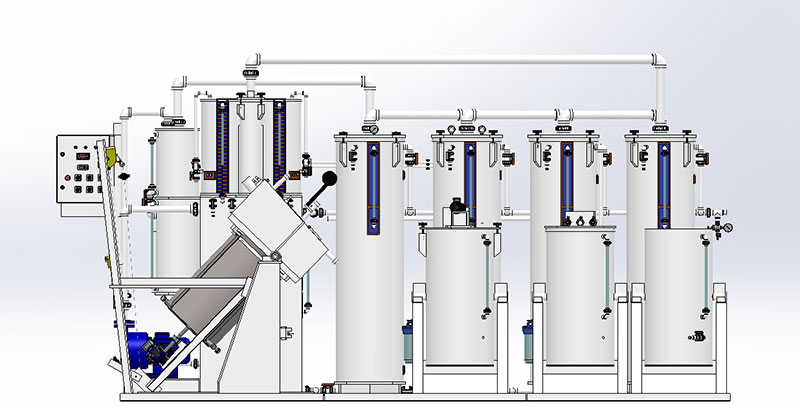

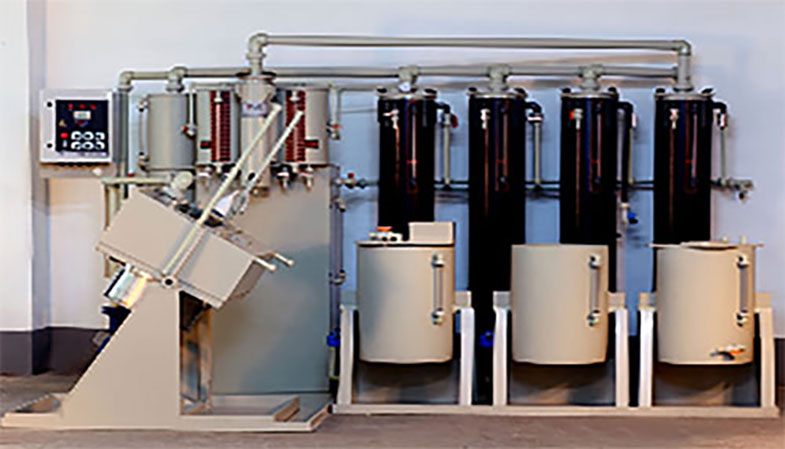

WASTEWATER NEUTRALIZATION MACHINE

It is designed to completely remove 100% of the metals present in acidic wastewater generated in workplaces where acids are utilized, to neutralize this wastewater and then to discharge it into the sewerage system.

The neutralization system has 4 compartments;

1st compartment is for recovery of precious metals (gold, platinum, palladium) present in waste acid.

2nd compartment recovers the copper in waste acids. The system returns copper in metal form.

3rd compartment is the pH adjustment compartment. It converts acid waters having a pH of 8 into neutralized water.

Residual matter is collected in the 4th compartment by passing the water neutralized through a filter press in the 3rd compartment;

this residual is settled after being tested in the 4th compartment and discharged from the weir into the channel after the settlement process.

İSKİ wastewater discharge permit belonging to Özkaradeniz Recycling (Cemil Kılıç) that uses this exact machinery.

Wastewater neutralization machinery implemented to the facility by our company in June of 2017 was inspected several times by İSKİ (Istanbul Water and Sewerage Administration) and the effluent was approved to meet İSKİ wastewater discharge standards. This wastewater discharge permit was hence issued for the company to certify that they were allowed to directly discharge their effluent into the sewerage system.

ENVIRONMENTALLY SENSITIVE ELECTRONIC WASTE RECYCLING SYSTEMS

THE MAJOR PROBLEM IN ELECTRONIC WASTE RECYCLING IS THE EFFICIENCY:

Recycling companies that focus mainly on gold tend to overlook the Copper content during acidic process which makes them unable to recycle this content, and they also waste most part of the Palladium along with Copper.

All inputs (plastics, precious metals and semi-precious metals) are completely and 100% recycled within the systems constructed according to projects we conceptualize.

Since the only waste generated through this system is breathable air and almost drinkable water, we can comfortably state the recycling rate to be 100%.

Card and Cable Crushing and Separation Machine

This machine crushes and grinds the electronic cards; separates plastics and magnetic material; and returns the non-magnetic matter containing the precious metals ready to go for the melting process.

Copper Electrolysis System

This is the most affordable, effective and environmentally friendly system for recovering copper that is the most important metal to be recovered in electronic waste as pure copper; and collecting anode slime that contains all precious metals within. This also is an indispensable/integral procedure for electronic waste recycling.

30 and 50-kg Capacity Induction Melting Furnace

Metal melting furnace with hydraulic tilting that can utilize Silicon carbide melting pot or neutral lining, which can heat up to 1400 degrees Celcius.

ORE ANALYSIS AND GRADE DETECTION LABORATORY

We construct a fully-equipped laboratory for analyses of precious metal ores and metals containing gold, silver, platinum and palladium; and provide cupellation system analysis training.

*Call us for Ore and Metal Analysis Method Training.

Fully Equipped Grade Detection Laboratory

Induction cuppel and melting furnace for ore analysis

This is a specially modified induction melting furnace for melting the sample by cuppelation method during ore analyses.

Ring mill for sample analysis

This is a 100-200 grams-capacity laboratory-type grinder designed for grinding the sample ore to the required fineness during ore analysis process.